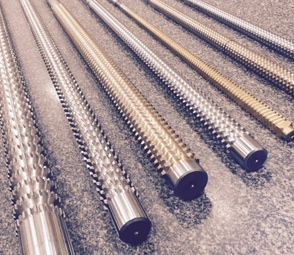

In addition to our broaching machinery design and engineering, Ohio Broach & Machine Company offers in-house production contract broaching services. We can perform internal broaching, broaching of irregular shapes, blind spline broaching, and surface broaching. Because we build our own machinery and tooling, we have the experience to broach nearly any shape including but not limited to gear forms, polygons, involute splines, and plier forms. Our in-house machinery includes vertical, horizontal surface, CNC shaper pull down machines. For customers who do not have the requirements or the capacity for a broaching machine in their facility, our in-house production broaching service can provide quality broaching for production sizes from short to long runs.

We broach nearly all metals including aluminum, brass, copper, stainless steel, and carbon steel, as well as non-metals including wood composites, plastic, hard rubber, and graphite. Our shaper works at depths between 1/4” and 1.5”, and can handle pieces with a diameter of up to 10”. Stroke length on our broaching machines range from 24” to 90” and cutting force range from 2 to 35 tons. Our capabilities allow us to produce parts for goods as varied as pliers, firearm receivers, saw blades, and transmission gears. For more information about our production broaching services, please see the table below, or contact us directly.

Menu

Menu