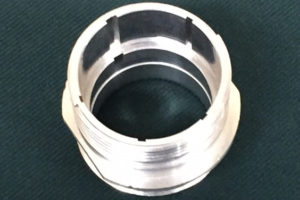

Some of the parts that have been machined on The Ohio Broach & Machine Company’s CNC Shaper machines are shown in the pictures below. These parts include electrical connector sleeves and a steering drive component for pickup trucks. These parts were broached on two different models of machines. The first three (2) pictures show various electrical connector sleeves with an array of different slots and forms on each of the parts. Each of these parts we broached on a single spindle shaper using a high speed special shaping tool conformed to the different slots. The first picture shows some internal slots that varied in position as well as three (3) different widths. The internal slot tools were a specialty high speed steel tool configured in the three different widths. The part was fixture in a servo-driven index table with collet clamp fixture to hold the part. The fixture was programmed to index to the proper location for each of the internal slots. Once positioned, the shaper head, moving at 600 stokes per minute for a 2 inch stroke, would progressively cut into the part until the depth was obtained. The part would then index to the next slot to be machined. The usual piece had 5 slots and they would be completed in one fixturing in about 45 to 50 seconds. These parts were broached on our ‘OHIO’ shaper model OB-VM16-2.

The steering drive component was done on our “OHIO’ CNC shaper model OB-VM16-2X outfitted with a dual shaper head and dual servo-driven indexing tables. This particular machine did two (2) parts at a time with a total cycle of one (1) minute. Each minute completed two (2) parts for the six-splined internal shape. The dual shaper head stroked 600 times per minute and carried a single edge special form carbide insert on each station. The dual station index table was driven by one servo motor. Due to the volume of parts per year, two (2) machines were required for the yearly production.

Please visit the rest of our website for more details on other services we provide.

Menu

Menu